Facilities

The Department has excellent teaching facilities with modern lecture theatres, dedicated computer suites and well-equipped teaching and research laboratories.

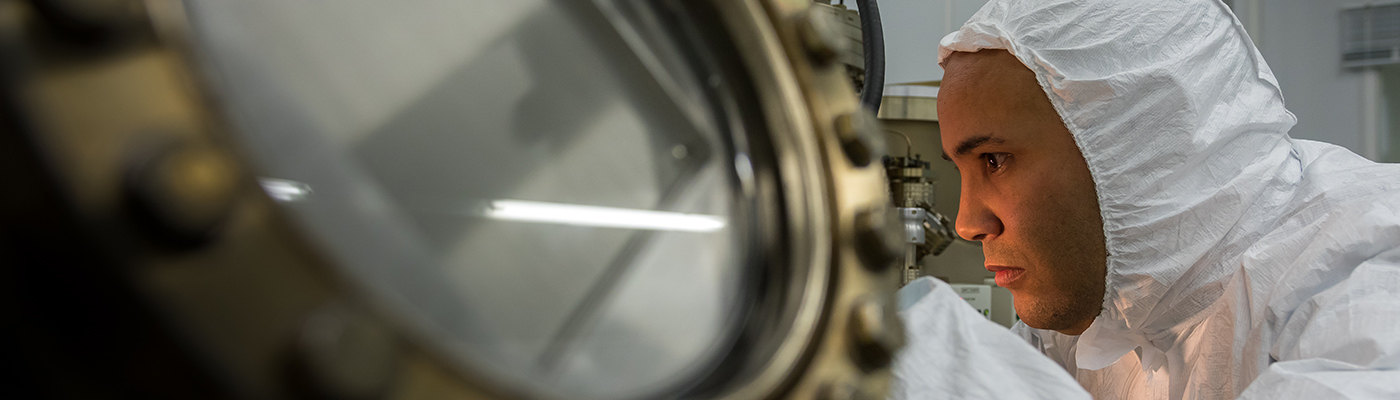

Our laboratories include clean rooms, a modern facility for molecular beam epitaxy and one of the highest specification high voltage laboratories in the UK.

We are working hard to ensure we are able to provide safe access to these facilities in line with the latest government advice. The safety and wellbeing of our staff and students is our highest priority and we will be providing health and safety briefings as part of your induction.

Flagship facilities

High Voltage Lab

Significant investment is being made into our electrical networks at a pace unparalleled in recent years.

Photon Science Institute

The Photon Science Institute was established to maximise the potential applications of photon science.

Rolls-Royce University Technology Centre

The Rolls-Royce University Technology Centre is the focal point for research on power conversion systems.

Centres and institutes

We have a presence in various research centres and institutes, aiding research and facilitating new discovery.

Other facilities

III-V processing

The class 100 III-V integrated circuit laboratory houses equipment for the fabrication of ultra fast transistors, optical devices (high efficiency Solar cells) and high sensitivity magnetic sensors. The complexity ranges from single devices with sizes in the nm range to complete integrated circuits on chip sizes 4x4 mm2.

III-V Integrated circuit Lab

- 6" Deep UV Lithography (0.5 μm)

- Reflow technology (0.2 μm)

- RIE

- Dielectric Deposition

- Metal Deposition6" furnaces

- In situ electrical characterisation

Modelling Software

- SILVACO (Physical)

- aADS

Anechoic Chamber

The anechoic chamber can be used for testing in microwave frequencies. It is designed to absorb reflections of electromagnetic waves above 1 GHz. Typical equipment under test is mobile & telecom antennas, as well as electronic products using wireless communication techniques.

- Physical size of the room 2.5m x 1.5m

- Able to measure from 1GHz and above, up to 26.5GHz

- Limited accuracy below 1GHz due to partial absorption of reflections at lower frequencies

- DAMs antenna pattern measurement systems

- Rotation in horizontal covering 360 degrees

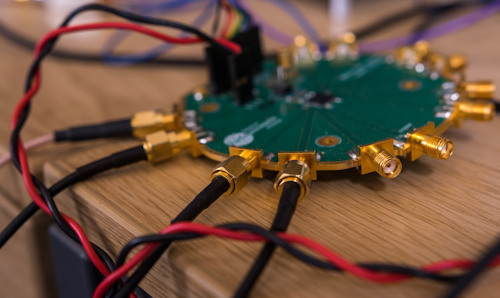

Aperture Array

The aperture array is a finite active antenna array for receiving only; LNAs are integrated for each antenna element. It can be used for beamforming solution testing, high gain reception, etc.

- Physical aperture size 1.25m x 1.25m

- Operation Frequency 400MHz – 1.4 GHz

- 64 antenna elements for each polarisation, dual polarised

- Each antenna is integrated with one LNA, 25 dB gain

- Outputs of the each LNA are differential with SMA connectors

- The LNAs are powered from the output ports with 5 volts.

The University of Manchester Botanical Grounds

Facilities for creating and testing novel electronic devices which interface with the human body, invasively and non-invasively (eg: wearables). These fall into two categories:

- Specialist items for low frequency/low voltage/low power testing in the 0-1 kHz region where the human body operates, with significant flicker noise and signal amplitude challenges.

- Gold standard devices for representative testing across a wide range of temperatures, interference sources (eg: motion) and similar.

Key items:

- Electrical testing

- Keysight N9020B signal analyser with baseband option for DC – 26GHz spectrum analyser and I/Q measurements.

- ESPEC SH-222 temperature and humidity controlled testing chamber.

- Keysight 9000 and 2000 series mixed signal oscilloscopes for analogue and digital testing.

- 2x Digitimer DS4 current sources.

- D179 signal attenuator for uV signal generation.

- Keithley 2450 nA source-measure units.

- Keithley 2231A-30-3 triple power supply.

- National Instruments 6221 data acquisition unit.

- Nvidia Titan XP GPU for AI acceleration.

Human body monitoring

- Brain Products ActiChamp 32 channel active electrode electrophysiological recorder.

- 2x Enobio 8 channel electrophysiological recorder, with SIGGI II impedance meter.

- Camntech actiwave wearable ECG unit, and Camntech acticardio wearable ECG unit.

- Neuroconn DC stimulator plus for electrical stimulation with remote and signal out options.

- Lifespan TR1200i treadmill and C3i exercise bike for motion artefact generation.

- 6x Shimmer Consensys body area network nodes.

- Various wearable devices: 2x Apple Watches, 5x Empatica E4, 4x Fibtbit ionics, 4x TI AFE4403 EVM watch, 8x Omron wireless blood pressure monitors. Mixture of Samsung Galaxy and Apple smartphones.

General tools

- Lulzbot mini 3D printer.

The bioelectronics suite supports a wide range of electronics development activities, particularly around the creation of ‘closed loop’ devices for simultaneous monitoring and stimulation of a biological agent. Bioelectronics is an important area for the University and will form part of the bio-suite in the Royce Institute of Advanced Materials.

Dielectrics lab

The dielectric materials laboratory is fully equipped with a wide range of facilities to pre-process and characterise liquid, gas and solid dielectric materials.

The main instrumentations/facilities in the lab include,

- Headspace/liquid gas chromatography mass spectrometry unit with flame ionisation detector and thermal conductivity detector

- Particle counter

- Karl fisher titrator for moisture measurement

- Potentiometric titrator for acidity measurement

- Kinematic viscometer

- Dielectric constant, tan delta and resistivity tester

- AC Breakdown tester

- Fume hood

- Vacuum and air circulating ovens

The instrumentations are mainly used to characterise the physical, chemical and basic dielectric properties of insulation materials including conventional materials and alternative materials that have better performance and less environmental impact. Facilities are also available for pre-processing the dielectric materials to the desired conditions for high voltage testing and ageing study.

Electric machine test stands

Our aircraft electrical demonstrator, machine design and condition monitoring test systems are all based on a range of electrical drive systems. A significant number of these drives are bidirectional enabling prototype motors and generators to be tested at up to 115kW and 15000rpm.

The capability of some of our machine test stands are:

- 115kW 15000rpm vector controlled bidirectional induction machine drive

- 115kW 3000rpm vector controlled unidirectional induction machine drive

- 7.5kW 2000rpm vector controlled bidirectional induction machine drive

- 30kW bidirectional DC machine drive

Energy storage and battery test systems

Energy storage is becoming a key priority for many applications ranging from transport to renewables and AC-grid systems. The Group has recently received significant investment from EPSRC to enhance our facilities for the characterisation and system integration of high-power energy storage technology.

Our energy storage test suite includes:

- 1MJ supercapacitor-based energy storage system

- Six Maxwell 48V 165F modules

- Dual-interleaved DC/DC boost converter

- dSPACE supervisory control

- NH Research 9200 battery tester

- Four 120V 200A channels

- Two 40V 600A channels

- Enerchron software

- ESPEC AR680 environmental chamber

- 680litre capacity

- +180°C to -70°C range

- 100% relative humidity control

- Commanded by Enerchron

- Ivium Vertex/100A booster

- Single 10V 100A channel

- Performs potentiostatic and galvanostatic tests

- Enables electrochemical impedance spectroscopy analysis

- ESPEC LU-124 climate controlled chamber

- 206litre capacity

- +85°C to -20°C range

The Intelligent Electrical Power Networks Evaluation Facility (IEPNEF)

IEPNEF provides a unique capability to examine more-electric aircraft power systems.

The IEPNEF is a 100kW facility that has been installed at Manchester as part of a national project to devise and develop more-electric technologies for future aircraft and land-based vehicles and examine system interactions. IEPNEF is a key component of the Rolls-Royce UTC and also forms part of the University's Aerospace Research Institute and Energy@Manchester.

The IEPNEF was established at Manchester by a £1 million investment from Rolls-Royce and the MoD under the Systems Engineering for Autonomous Systems Defence Technology Centre. IEPNEF provides a unique capability to examine more-electric aircraft power systems. In the 100kW facility, hardware-in-the-loop techniques are used to provide an aero-engine emulator that drives real generator hardware supplying a four-bus reconfigurable network.

Active work packages in the Rolls-Royce-sponsored IEPNEF include:

- platform level power management;

- advanced generator control schemes;

- emulation of mechanical prime mover.

Molecular Beam Epitaxy Facility - Microelectronics and nanostructures

The University of Manchester is one of the UK's leading centres of excellence in semiconductor materials and electronics.

Facilities include:

- 60 m2 class 1000 cleanroom for processing Si and polymers;

- several dedicated electrical characterisation laboratories;

- material characterisation;

- device processing and fabrication;

- characterisation and measurement.

Real Time Digital Simulator

Hardware in the loop simulator (HIL)

The Manchester RTDS is a key enabler in the development of novel Wide Area Monitoring, Protection and Control concepts for the next generation of Smart Transmission and Distribution Networks.

The Manchester RTDS simulator is the largest University-based hardware in the loop simulator in the UK and the second largest in Europe.

It is designed for hardware in the loop testing of physical equipment such as

- control and protection devices complex

- solutions involving a large number of intelligent electronic devices.

Specification

The Manchester RTDS is a digital system able to perform electromechanical and electromagnetic electric power system transient simulations continuously in real time, covering the frequency range DC to ~3kHz. It has 6 racks with 30 PB5 processor cards and 5 MMC units.

It is designed for hardware in the loop (HIL) testing of physical equipment such as control and protection devices, or complex solutions involving a large number of intelligent electronic devices.

Working with industry

The simulator is equipped with sufficient analogue and digital input and output facilities as well as communication capabilities using well known standards (eg, IEC 61850, C37.118 and IEC 60870).

This is particularly important for industry as it allows not only the development but also the adequate validation of future smart transmission and distribution network solutions.

Applications

Our RTDS is used in various ongoing initiatives at The University of Manchester and beyond, including

- integration of renewable energy sources,

- future low carbon loads,

- energy storage devices,

- multi-terminal HVDC transmission systems,

- development of concepts of Wide Area Protection and Control,

- communication aspects,

- development of Smart Grid solutions and concepts.